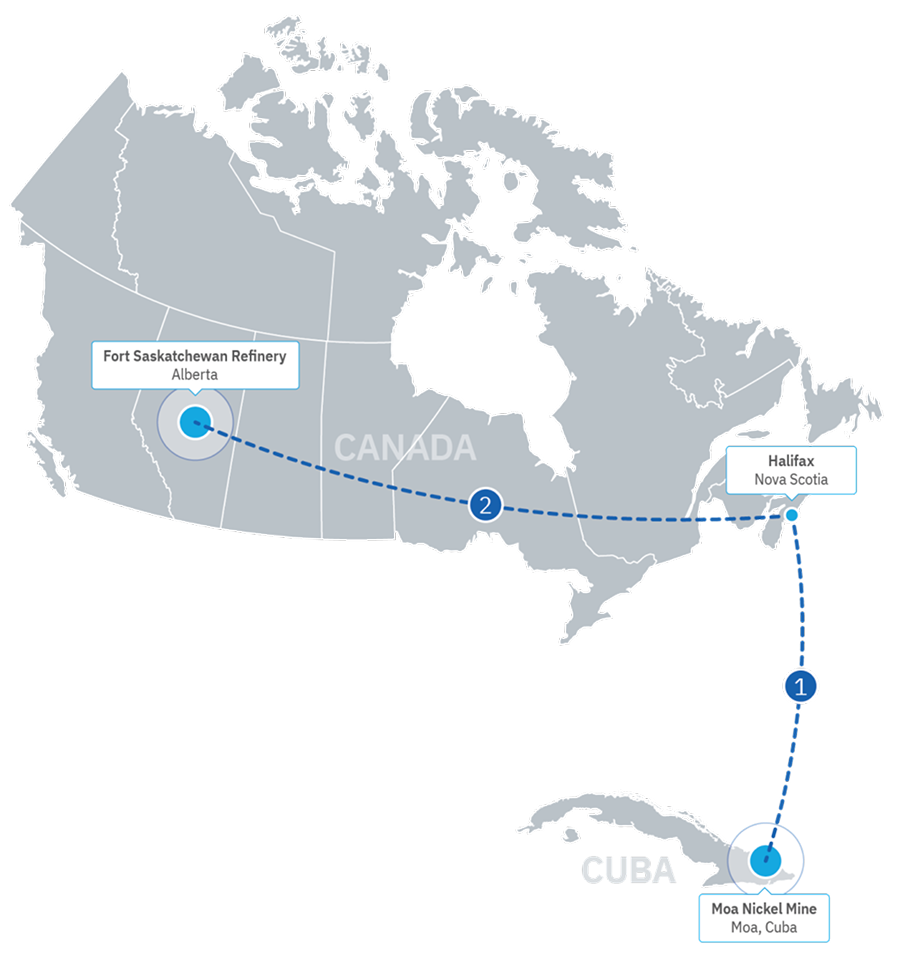

Sherritt’s Moa Joint Venture is a 50/50 partnership with General Nickel Company S.A. (GNC) of Cuba. The Moa JV is a vertically integrated joint venture that mines, processes and refines nickel and cobalt for sale worldwide (except in the United States). The joint venture has an open pit lateritic ore mine and processing facility in Moa, Cuba where ore is processed into mixed sulphide precipitate (MSP) containing nickel and cobalt. The MSP is transported to its refining facilities in Fort Saskatchewan, Alberta, Canada. The resulting nickel and cobalt products are sold to various markets, primarily in Europe and Asia. The Moa JV filed an updated National Instrument 43-101 Technical Report on March 31, 2023.

The refinery facilities in Fort Saskatchewan have an annual combined production capacity of approximately 38,200 tonnes (100% basis) of nickel and cobalt.

The Moa JV has a current estimated mine life of 25 years and has embarked on an expansion program focused on increasing annual MSP production by approximately 20% of contained nickel and cobalt (100% basis).

Sherritt’s Fort Site is a wholly-owned fertilizer business in Fort Saskatchewan that provides inputs (ammonia, sulphuric acid and utilities) for the Moa Joint Venture’s metals refinery, produces agriculture fertilizer for sale in Western Canada and provides fertilizer storage and administrative facilities.

Sherritt’s Metals Marketing includes its 100% interests in subsidiaries established to buy, market and sell Moa JV’s nickel and cobalt production and the Sherritt’s cobalt inventory received under the Cobalt Swap agreement.

The nickel laterite deposit in Moa, Cuba is mined using conventional open cut mining techniques using hydraulic excavators and articulated haul trucks. The Moa plant processes the mined ore into mixed sulphides using high-pressure acid leaching (HPAL).

Refining the Moa mixed sulphides and other feeds occurs in Fort Saskatchewan, Alberta. Feeds are blended and leached in an ammonia and ammonium sulphate solution. Nickel, cobalt and other metals are dissolved and sulphide sulphur is oxidized and combined with ammonia to form ammonium sulphate. Nickel and cobalt are recovered in powder form or compacted into briquettes.

After Nickel and Cobalt are recovered during the refining process, the remaining, essentially metal-free, solution is evaporated to crystallize ammonium sulphate, which is dried and sold as fertilizer. The on-site ammonium sulphate plant has an annual capacity of approximately 190,000 tonnes.

The nickel laterite deposit in Moa, Cuba is mined using conventional open cut mining techniques using hydraulic excavators and articulated haul trucks. The Moa plant processes the mined ore into mixed sulphides using high-pressure acid leaching (HPAL).

Refining the Moa mixed sulphides and other feeds occurs in Fort Saskatchewan, Alberta. Feeds are blended and leached in an ammonia and ammonium sulphate solution. Nickel, cobalt and other metals are dissolved and sulphide sulphur is oxidized and combined with ammonia to form ammonium sulphate. Nickel and cobalt are recovered in powder form or compacted into briquettes.

After Nickel and Cobalt are recovered during the refining process, the remaining, essentially metal-free, solution is evaporated to crystallize ammonium sulphate, which is dried and sold as fertilizer. The on-site ammonium sulphate plant has an annual capacity of approximately 190,000 tonnes.

1: Mixed sulphides are shipped by ocean vessel to Halifax.

2: Mixed sulphides are shipped by rail from Halifax to Fort Saskatchewan.

Notes: Routes are approximate. Map regions have been modified for

enhanced readability.